Lean Six Sigma Principles to Adopt Immediately for Business Growth in 2022

Lean Six Sigma Certification Online with Six Sigma methodology is a disciplined, structured, and data-driven approach to improving manufacturing processes. This is done by reducing defects to achieve quality which ultimately increases the profitability of the company. This approach focuses on prevention, not detection. Prevention means identifying and eliminating the causes of errors, which in turn reduces variability in the production process and leads to better product quality.

Six Sigma certification refers to the implementation of business processes. This is a measure of quality. Quality is measured at seven levels in terms of defects per million, with Six Sigma equivalent to 3.4 defects per million, which means quality perfection is 99.99966%, and this is the highest level.

Lean Six Sigma Green Belt Training

Apart from knowing what your customers want and need from your product or service, this is important because only 10-15% of process steps add value and only 1% of your total process time. The best way to start reducing waste and speeding up your processes is to make sure your customers are satisfied with your product or service, which can save you money while keeping your business running.

1. Understand the Value Flow - The value stream is bringing your product or service to the customer and getting paid for it. The value stream of a manufacturing company selling personalized items online, for example, includes all steps from ordering a product from a customer, through creating a product, to shipping the product to a customer.

You must document your value stream to ensure that each step in the process adds value or ensures a product or service meets the important quality standards you set out in Principle One. You need to describe this process in as much detail as possible so that you can identify all the steps involved and understand exactly how your business works. You have to go where the work is being done and stay there for a while to see how it's done, not how it's supposed to be done on paper. Data collection includes how everything was completed and how long each step took.

2. Analyse Problems and Build Effective Solutions - The practical solution to a problem depends on the analysis and analysis of the problem. Pay attention to actions that add value and those that don't so you can analyze every step of the process, from customer orders to payment to manufacturing and beyond. Remember to always consider how individual products are made, not batches, as this can help you spot problems with overproduction or bottlenecks in the process.

3. Confirm Your Business Process - Once you've documented the value stream, you can work to manage, improve, and streamline it. Identify any steps in the process that don't add value and decide whether to remove them, or at least make sure they don't slow down the processes that don't add value. Time must also be taken into account. If a product is kept on the shelf for months because it was made too early, it is of no use.

4. Reduce Waste and Simple - As a result of downsizing, each step flows seamlessly into the next. Identify if there is any wastage or excess in your value stream. Think how much you can save by reducing waste when you realize that your manufacturing facility can make smaller parts from leftover larger parts. For example, loggers may sell sawdust as a pet item and as a cleaning product.

Even if you can't turn your literal waste into revenue, try to reduce waste and eliminate things that don't add value to your final product or don't meet your important quality standards. For example, if employees have to wait a long time for a production process, they may find ways to work on other aspects of production, reducing their lost time and speeding up the entire production process.

Look for the eight forms of waste identified by the Lean methodology: transportation, wasted talent, movement, finish, waiting, defects, and overproduction.

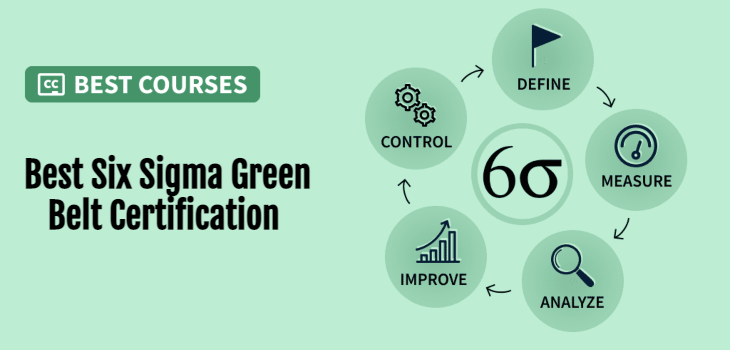

5. Data Improvement - Make sure you're using the data for something other than reducing variation. As you improve your product or service, you also need to collect, analyze and use data to further improve the value stream. Periodic assessments of your situation should be based on the well-known Six Sigma DMAIC. Define, measure, analyze, improve and control. If new processes need to be designed, Six Sigma DMADV should be used: Definition, Standards, Analysis, Design, and Verification.

Regardless of whether you want to do this or fix it, always use data to better understand the problem and analyze possible solutions. Be careful not to jump to the simplest conclusions or solutions and always proceed systematically. Instead of trying to solve a big problem all at once, break your problem down into smaller and larger parts. Lean Six Sigma Green Belt Training helps you to gain control over such things.

Read our published article on Print Media and ANI.

Conclusion

Make the right choice of the training program and become a certified Six Sigma professional. ISEL Global is an accredited training and consulting center offering professional courses worldwide. They provide results-based training and deliver accurate results while optimizing costs.

Past Events

-

-

2022-06-28 11:24:37 Lean Six Sigma Principles to Adopt Immediately for Business Growth in 2022 events

2022-06-28 11:24:37 Lean Six Sigma Principles to Adopt Immediately for Business Growth in 2022 events -

-

-

-

-

-

-

-

.jpg)

-

-

.webp)

-

-

2022-03-12 13:57:16 Top 10 Reasons Why You Should Go for Six Sigma Green Belt Certification in 2022 events

2022-03-12 13:57:16 Top 10 Reasons Why You Should Go for Six Sigma Green Belt Certification in 2022 events -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-