Improve your Supply Chain Management with Lean Six Sigma

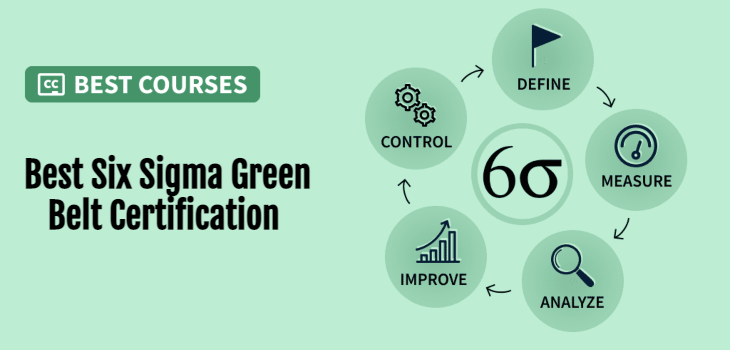

Six Sigma is a statistical-based improvement method. The basic idea is that the variation is bad. When managing a production process or supply chain, you need consistency and predictability. If you don't have consistency, a certain percentage of the things you do may not be good for your customers. When you have consistency—that is, when you control a process—the chances are that the product you create will be of much greater use. Consistent processes produce high-quality products. Statisticians describe process variability by a measure of deviation from the mean. The symbol used to denote deviations in mathematical equations is the Greek letter sigma (σ). Each data set for a process will have some variation, but the more sigma you have, the more stable your process will be. So, the statistical basis for Lean six sigma certification is to reduce the process variability in such a way that the error occurs only at the sixth sigma (6σ), or 3.4 times per million.

The most important thing you need to know about Six Sigma Certification is that the goal is to have a small number of defects—that is quality improvement – as a result of reducing process variation. You can achieve this by measuring processes and using mathematical tools to improve consistency.

Here is a list of some of the benefits of implementing Six Sigma for supply chain efficiency:

Reduce waste - Six Sigma aims to ensure that there is minimal waste in the supply chain. This waste can be related to a number of things, including lost time waiting for the next step and additional processing time if your team is not using cutting-edge chain management practices. With six sigma black belt certification, you can do it very efficiently.

Increase speed - When you enable Six Sigma, one of the best supply chain efficiency benefits you will get is increased speed. Because Six Sigma is based on completing all processes as quickly as possible and eliminating unnecessary processes. In this way, Six Sigma can help you ensure your orders are placed and filled faster.

Increase predictability - When you use Six Sigma, you will find that even if your supply chain processes have gone wrong in the past, they can quickly become more predictable when you apply continuous processes to your supply chain management. You can make order accuracy, inventory budgets, and delivery times more predictable when you use Six Sigma.

Reduce costs - One of the biggest problems in the supply chain is rising costs. Raw material costs, transportation, shipping costs, and labour costs may vary. This can really mess up your supply chain budget. Six Sigma will improve processes and reduce costs by creating a buffer between your budget and unexpected supply chain costs.

Identify problems better - When you accelerate the processes comprised in the six sigma green belt for your supply chain, one of the best benefits is that you can more effectively identify problems before they occur. If something is wrong with your supply chain processes, Six Sigma lets you see it because it is outside the normal operating procedures you use for supply chain and inventory.

Increase team engagement - Six Sigma requires that you empower your team members to make critical decisions about your supply chain issues without having to consult with a manager. This not only helps you make your team more independent, which reduces the number of decision-making barriers, but it also builds trust among your team members, making them more likely to do their best.

Increased Revenue – Companies that use Lean Six Sigma to make their supply chains more efficient can offer their customers a consistent level of service. Reliable service results in satisfied customers, which helps companies achieve greater cost efficiency and increased sales.

Read our published article on Print Media and ANI.

Organizations that apply Lean Six Sigma principles to their supply chains can create competitive advantages, increase sales, and boost employee morale. Implementing Six Sigma practices offers all sorts of supply chain efficiency benefits, from saving money to predicting future problems. If you want to know more reasons why you should include Six Sigma, take the time to delve into this philosophy in depth so you can determine whether Six Sigma is right for your supply chain needs.

Past Events

-

-

2022-06-28 11:24:37 Lean Six Sigma Principles to Adopt Immediately for Business Growth in 2022 events

2022-06-28 11:24:37 Lean Six Sigma Principles to Adopt Immediately for Business Growth in 2022 events -

-

-

-

-

-

-

-

.jpg)

-

-

.webp)

-

-

2022-03-12 13:57:16 Top 10 Reasons Why You Should Go for Six Sigma Green Belt Certification in 2022 events

2022-03-12 13:57:16 Top 10 Reasons Why You Should Go for Six Sigma Green Belt Certification in 2022 events -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-