Become an expert in six sigma methodology by getting hands-on knowledge on DMAIC, Project Charter, Process Capability, FMEA, Sigma calculation, Test of Hypothesis, Control Charts, VSM, JIT using real case scenarios and real-life examples. The course is aligned and accredited to IASSC & ASQ and integrates Six Sigma, Lean, and DMAIC methodologies using live projects.

The course features world-class content with live projects and MINITAB PRO-driven data analysis training with end-to-end support in project implementation by Master Black Belt Experts and Trainers.

The Six Sigma Green Belt Certification is aligned and recognized by The Council for Six Sigma Certification & The International Association for Six Sigma Certification USA. The certification also acknowledges the BOK outline of The American Society for Quality, USA.

Global Recognition of Your Certification

A person with Six Sigma certification has problem-solving abilities. Someone may gain Green Belt, Black Belt, or Master Black Belt Certification. The higher the certification one attains, the more is the ability to solve complex organizational problems. Six Sigma certification is a process of individual’s knowledge validation using a classification system, generally referred to as “Belts” ( Green Belt, Black Belt, Master Black Belt ) This verification test individual commands over six sigma methodology and tools. The belt classification shows the position these certified individuals would occupy in an organizational structure and job roles.

| Participants INTRODUCTION & ROTI ( Return on Training Investment) setup | A brief intro of participants & Learning objective | ||||||

| Expectation setup from the workshop | |||||||

| An overview to lean six sigma benefits, application, and relevance in participants profile | |||||||

| Guide to download MINITAB | |||||||

| Live project selection | |||||||

| Guide to using and download Templates and Toolkits application for Project work | |||||||

| Overview to QUALITY and LEAN SIX SIGM | History of Quality (Deming, Juran, Ishikawa, Taguchi, etc.) | ||||||

| Evolution of Six Sigma | |||||||

| Evolution of LEAN manufacturing | |||||||

| Six Sigma – philosophy and objectives | |||||||

| Deliverables of a Lean Six Sigma Project | |||||||

| Project Management Fundamentals | |||||||

| Six Sigma Roles & Responsibilities | |||||||

| LEAN SIX SIGM framework and how dose it work | Meanings of Six Sigma | ||||||

| Data driven decision making | |||||||

| The Problem Solving Strategy Y = f(x) | |||||||

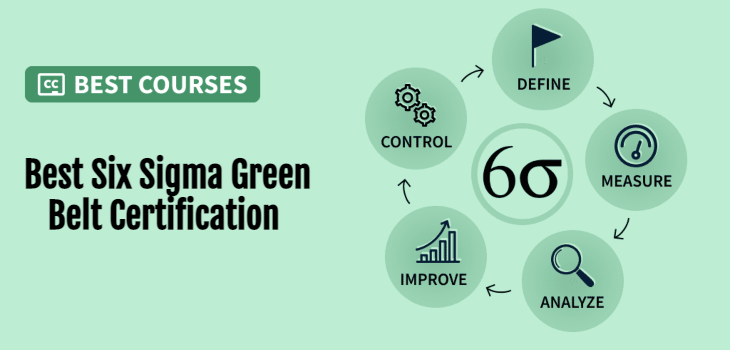

| Understanding How DMAIC and DMADV frame work | |||||||

| Documenting STAKEHOLDER REQUIREMENTS | SIPOC - Identifying stakeholders and customers | ||||||

| Determining critical requirements | |||||||

| Identifying performance metrics | |||||||

| QFD - Quality Function Deployment | |||||||

| Voice of the Customer, Business and Employee | |||||||

| DEFINE PHASE tools | Project selection , Project prioritization, KANO Model, Juran's customer needs | ||||||

| Preparing project charter | |||||||

| Initiating teams, Stages of team evolution | |||||||

| Mapping As - is process flow | |||||||

| Understanding Critical to Quality (CTQ) and VOC to CTQ drill down | |||||||

| Cost of Poor Quality (COPQ) and its types | |||||||

| MEASURE PHASE tools | Understanding of Data , Types of Data , Dimensions of Data | ||||||

| Population Data (VS) Sample data , Sampling Techniques | |||||||

| Sample Size calculation, Confidence level and confidence interval | |||||||

| Data collection template and techniques | |||||||

| Measurement system analysis - Calibration, Gauge R&R, KAPPA analysis | |||||||

| Central Limit Theorem | |||||||

| Stability and Distribution types | |||||||

| Descriptive statistics (Measure of central tendency & Measure of variation) | |||||||

| Base Line sigma calculation (DPU, DPMO, Cp,Cpk) | |||||||

| ANALYZE PHASE tools | 7 QC Tools (Histogram, Cause-and-Effect Diagrams / Fishbone Diagram, Pareto charts, Control Charts, Scatter diagrams, Process Mapping, Check Sheet) | ||||||

| 5 Why Analysis , Control impact matrix, Tree Diagram, Affinity clustering | |||||||

| Data visualization - Box Plot, Multi Vari charts Trends and comparison charts | |||||||

| Hypothesis testing - Parametric test (Continuous Data , Discrete Data) Alpha & Beta errors | |||||||

| LEAN METHODOLOGY | Fundamentals of lean , 5 principles of lean | ||||||

| Value add (VS) non value add and 8 Types of deadly waste | |||||||

| Value stream mapping - Lead Time, Processing Time, Cycle Time, Turnaround Time, First Pass yield, Rolled Throughput Yield, Process Cycle Efficiency | |||||||

| Heijunka - Leveling, Sequencing, Stability, TAKT time | |||||||

| Jidoka, Poke Yoke, Autonomation, Built-in Quality, Stopping at Abnormalities | |||||||

| Visual Management, 5 S implementation | |||||||

| JIT (Just in time), Critical level of replenishment , Supermarket or consumption based replenishment, Kanban | |||||||

| Kaizen, LEAN action work out (AWO) | |||||||

| IMPROVE PHASE tools | Solution design matrix, Brain storming | ||||||

| Failure Mode effect analysis | |||||||

| Regression techniques - Simple linear regression , Multiple regression | |||||||

| Design of experiments (DOE), Taguchi robustness concepts | |||||||

| Basics of solution generation through "Design Thinking Concepts" | |||||||

| "Six Thinking Hats" - Dr. Edward de Bono | |||||||

| CONTROL PHASE tools | Statistical process control | ||||||

| Control plan for sustaining benefits | |||||||

| Introduction to Control Charts and Types of Control Charts | |||||||

| PROJECT DOCUMENTATION and Sustenance | CBA - Cost benefit analysis | ||||||

| Project documentation as per DMAIC frame work | |||||||

| Horizontal deployment of lessons learned | |||||||

| Inculcating LEAN SIX SIGMA DNA in all layers of organization | |||||||

From the course:

- Learn the principles and philosophy behind the Six Sigma technique

- Learn to apply statistical methods to improve business processes

- Design and implement Six Sigma projects in a practical scenario

- Learn the DMAIC process and various tools used in Six Sigma methodology

- Knowledge of Six Sigma Green Belt Professional enables you to understand real-world business problems, increase an organization’s revenue by streamlining the process, and become an asset to an organization

- According to Villanova University, employers such as United Health Group, Honeywell, GE and Volkswagen have been actively seeking professionals with Six Sigma to fill a variety of positions

- The Training enhances your skills and enables you to perform roles like Quality Manager, Quality Analyst, Finance Manager, Supervisor, Quality Control, etc.

According to Indeed.com, the national average salary for a Six Sigma Green Belt is $72,000 per year in the United States.

From the workshop:

- Instructor LED training by Six Sigma Black Belt and Master Belt experts to make candidate learn the real scenario of six sigma tools and methodology

- Learn the principles and philosophy behind the Six Sigma method

- Dummy project by instructors to make candidate get a hands-on six sigma projects

- Downloadable Six Sigma PPT & Six Sigma PDf

- Industry Based case studies

- High-Quality training from an experienced trainer

- The Program extensively uses Minitab, specialized statistical software. It provides you with a thorough knowledge of Six Sigma philosophies and principles (including supporting systems and tools).

- Know about six sigma certification cost and six sigma green belt certification cost.

The Six Sigma program is designed for professionals and students who want to develop the ability to lead process improvement initiatives. Six Sigma tools and process is widely used in all business processes. Six Sigma is applicable in all industry and in all functional areas.

An indicative list of participants in our Green Belt program could include:

- Financial/business analyst

- Commodity manager

- Project manager

- Quality manager

- Production manager

- Production Engineer

- Business development manager

- Manufacturing process engineer

- Continuous improvement director

- Business managers or consultants

- Project manager/Program Manager

- Director or VP of operations

- CEO, CFO, CTO

On successful completion of the course and course requisites, the candidate will receive an Internationally accredited and globally recognized Certified Six Sigma Green Belt Certification.

This course offers the Six Sigma Certification Validation Tool for Employers

Your Six Sigma Certification Validation Tool can be used by employers, clients, and other stakeholders to validate the authenticity of your Six Sigma Certifications you have received. Using the programming code located on your certified LSSGB certification, one can see all your training and certification details online.

.jpg)

.webp)