What is Six Sigma?

Six Sigma is a quality program that, when learned and successfully implemented, improves the customer’s experience, lowers business costs, and increases revenue. Six Sigma is a management strategy, a set of tools and techniques that helps eliminate the eros and defects in a business process. It’s a data-driven analysis, that uses statistics to improve business processes and solve complex business problems.

What is Six Sigma Certification?

Six Sigma Certification is a short-term, skill enhancement course. A person with the Six Sigma certification has strong analytical and problem-solving abilities. Someone may gain Six Sigma Yellow Belt, Six Sigma Green Belt, Six Sigma Black Belt, or Six Sigma Master Black Belt certification. The higher the certification one attains, the more is the ability to solve complex business problems. Six Sigma certification is a process of individual knowledge validation using a classification system, generally referred to as “Belts” ( Yellow Belt, Green Belt, Black Belt, Master Black Belt ) This verification test individual commands over six sigma methodology, techniques, and tools. The belt classification shows the position these certified individuals would occupy in an organizational structure and job roles.

Six Sigma Yellow Belt Certification

Six Sigma Yellow Belt is the first-level belt of the six sigma family. It is a starting level course for people who are new to the six sigma world and covers the basic understanding of the six sigma process and fundamentals. The yellow belt ensures that participants should have sound knowledge of six sigma methodology and they become aware of standard tools of six sigma. Yellow belt certification is nowadays obsolete, is not much in demand in the industry. The topics and curriculum of the Yellow belt are now merged in the green belt.

Six Sigma Green Belt Certification

The second level belt of the six sigma family and is one of the most demanded and recognized levels of six sigma. The six sigma green belt certification allows individuals to start working on six sigma projects as project members. Green Belt holders are well versed with six sigma tools, their application, and utilization. They know how to work on six sigma projects and solve complex organizational problems. The Six Sigma Green Belt generally operates or works under the supervision of the Six Sigma Black Belt.

Six Sigma Black Belt Certification

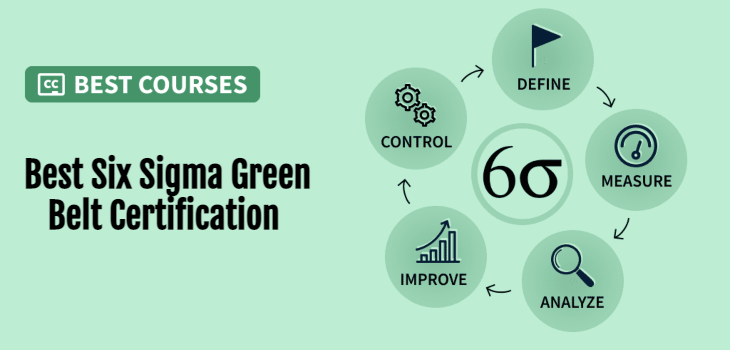

The third level belt of the six sigma family and the most advanced level certification. Black Belt holders are professionals who are expected to work as a six sigma project owner or leader and guide and mentor green belt holders under them. A Black Belt should demonstrate team leadership, change management, understand team dynamics and assign team member roles and responsibilities for completing the six sigma projects. Black Belt holders are proficient in six sigma DMAIC methodology, DEFINE | MEASURE | ANALYSE | IMPROVE | CONTROL.

Six Sigma Master Black Belt Certification

A rank assigned to an experienced and effective six sigma expert. Six Sigma Master Black Belt is generally responsible for a portfolio of improvement projects, leading enterprise-wide Six Sigma implementations, and training/mentoring others in Six Sigma. Master Black Belt holders are people at the executive level, aiming for a vision to bring a culture of six sigma within the department or organization. MBB is responsible for understanding the requirements from stakeholders or management and accordingly deploying the Black Belt holders to suffice and complete the requirements.

Six Sigma Certification Online Training

Six Sigma Green Belt & Black Belt training is especially for the future project leaders of Lean & Six Sigma projects. We deliberately mix non-profit with profit participants. There will then be fun, useful discussions and knowledge exchanges during the training sessions. In addition, there are also many self-employed people who follow the LSS Green Belt training to increase their expertise as in a trimmer.

The unique methodology for training and project support is something that differentiates ISEL GLOBAL from other training institutes. We train you on the basis of the experience which we have gained from the Six Sigma Certification Consulting we do for our clients. We help you understand the actual challenges faced and how to overcome them while running a Six Sigma project.

Day 1: Introduction To Lean Six Sigma Green Belt

- A brief intro of participants & Learning objective

- Expectation setup from the workshop

- An overview of Lean, Six Sigma and Basic understating of Lean Six Sigma as a combined strategy

- General examples and usage of Lean Six Sigma in similar companies and other industry

- An overview to lean six sigma benefits, application and relevance in participants profile

- Guide to download MINITAB

- Live project Selection

- Guide to using and download Templates and Toolkits application for Project work

Day 2: Overview of Lean Six Sigma and the Organization

- Lean Six Sigma and organizational goals

- Value of Lean six sigma

- Organizational goals and Lean Six Sigma projects

- Organizational drivers and metrics

- Lean principles in the organization

- Lean concepts

- Value-streaming mapping

- Design for six sigma (DFSS) methodologies

- Roadmaps for DFSS

- Basic failure mode and effects analysis (FMEA)

- Design FMEA and process FMEA

Day 3: Define Phase of Six Sigma with Voice of the customer (VOC) & Project management basics

- Project identification

- Project Selection

- Process elements

- BenchMarking

- Process inputs and outputs

- Owners and stakeholders

- Customer identification

- Customer data

- Customer requirements

- Project charter

- Project scope

- Project metrics

- Project planning tools

- Project documentation

- Project risk analysis

- Project closure

- Management and planning tools

- Business results for projects

- Process performance Communication

- Team dynamics and performance

- Team stages and dynamics

- Team roles and responsibilities

- Team tools

- Team Communication

Day 4: Measure Phase of Six Sigma

- Process analysis and documentation

- Probability and statistics

- Basic probability concepts

- Central limit theorem, Statistical distributions, Collecting and summarizing data

- Types of data and measurement scales

- Sampling and data collection methods

- Descriptive statistics

- Graphical methods

- Measure Phase (contd E. Measurement system analysis (MSA) F. Process and performance capability

- Process performance vs. process specifications

- Process capability studies

- Process capability (Cp, Cpk) and process performance (Pp, Ppk) indices

- Short-term vs. long-term capability and sigma shift

Day 5: Analyze Phase of Lean Six Sigma

- Exploratory data analysis

- Multi-vari studies

- Correlation and linear regression B, Hypothesis testing

- Basics Tests for means, variances, and proportions

- Introduction to MINITAB Data analysis

Day 6: Improve Phase of Lean Six Sigma

- Design of experiments (DOE)

- Basic terms, DOE graphs, and plots

- The root cause analysis

- Lean Tools 1. Waste elimination 2. Cycle-time reduction 3. Kaizen and kaizen blitz V1.

Day 7: Control Phase of Six Sigma

- Statistical process control (SPC)

- SPC Basics

- Rational subgrouping

- Control charts

- Control plan

- Lean tools for process control

- Total productive maintenance (TPM)

- Visual factory

- Project Implementation & Support

- MINITAB Practice and guidance for project

- Project implementation support

- Templates and Toolkits application for Project work

- Support on Data Project, Implementation and project completion

Become a Six Sigma Certification professional with internationally accredited CLSSGB certification program.

From the course:

- Learn the principles and philosophy behind the Six Sigma technique

- Learn to apply statistical methods to improve business processes

- Design and implement Six Sigma projects in the practical scenario

- Learn the DMAIC process and various tools used in six sigma methodology

- Knowledge of Six Sigma Professional enables you to understand real-world business problems, increase an organization’s revenue by streamlining the process, and become an asset to an organization

- According to Villanova University, employers such as United Health Group, Honeywell, GE, and Volkswagen have been actively seeking professionals with Six Sigma Certification to fill a variety of positions.

According to Indeed, the national average salary for a Green Belt Professional is $72,000 per year in the United States.

According to recent surveys, the median salary for certified professionals in this field is approximately $83,107 per year.

The Six Sigma Certification program is designed for professionals and students who want to develop the ability to lead process improvement initiatives. Six Sigma tools and the process is widely used in all business processes. Six Sigma Certification is applicable in all industry and in all functional areas:

An indicative list of participants in our Green Belt program could include:

| Financial/business analyst | Commodity manager | Project manager |

| Quality manager | Production manager | Production Engineer |

| Manufacturing process engineer | Continuous improvement director | Business managers or consultants |

| Project manager/Program Manager | Director or VP of operations | CEO, CFO, CTO |

On successful completion of the course and course requisites, the candidate will receive Internationally recognized Six Sigma Certification.

Six Sigma Certification Accredited by CSSC & Amercian Board, USA.

This course offers Six Sigma Certification Validation Tool for Employers

Your Six Sigma Certification Validation Tool can be used by employers, clients, and other stakeholders to validate the authenticity of your Certifications you have received. Using the programming code located on your certified LSSGB certification, one can see all your training and certification details online.

.jpg)

.webp)