With the Lean Six Sigma dual degree combo program, you will gain in-depth knowledge and critical skills in Lean Management, Lean Six Sigma Green Belt, MINITAB PRO, and Lean Six Sigma Black Belt. Get yourself ready for industry high-paying jobs in fortune 500 companies, as almost all fortune organizations, from Manufacturing & Service sector, are demanding and giving high preference to Lean Six Sigma Certified Professionals.

The course features end-to-end support on live project implementation in Green Belt & Black Belt, with MBB support and MINITAB data simulations.

This dual degree master's program helps you grow your career as a Lean Six Sigma Expert Professional by preparing you from basic to advance level of lean six sigma methodology.

Global Recognition: World’s Highest Accredited Certification

- Lean Six Sigma Curriculum and Certification Accredited by The Council of Six Sigma Certification, USA

- Certification Accredited by The International Quality Federation, USA

- Certification acknowledging the curriculum and BOK outline of American Society of Quality, USA

- Course Approved by Ministry of Skill Development & Entrepreneurship, Govt. of India

- Certification accredited by the UKAC United Kingdom

- Certification accredited by American Board, USA

The program offered is a live interactive virtual classroom program with multiple sessions on weekends. This program features expert support, live projects, MINITAB PRO simulations, world-class material, and 24*7 support to all learning-related queries.

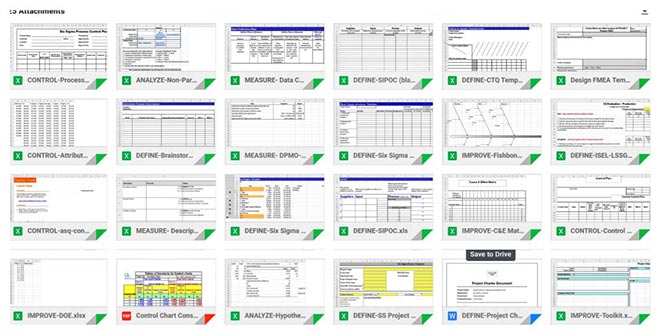

Get Access to 100+ Project Analysis Templates for Project Work

Six Sigma Project Templates for Analysis

| Participants INTRODUCTION & ROTI ( Return on Training Investment) setup | A brief intro of participants & Learning objective | ||||||

| Expectation setup from the workshop | |||||||

| LSS benefits, application, and relevance in participants' profile | |||||||

| Guide to download MINITAB | |||||||

| Live project selection | |||||||

| Guide to Templates and Toolkits application for Project work | |||||||

| Overview to QUALITY and LEAN SIX SIGM | History of Quality (Deming, Juran, Ishikawa, Taguchi, etc.) | ||||||

| Evolution of Six Sigma | |||||||

| Evolution of LEAN manufacturing | |||||||

| Six Sigma – philosophy and objectives | |||||||

| Deliverables of a Lean Six Sigma Project | |||||||

| Project Management Fundamentals | |||||||

| Six Sigma Roles & Responsibilities | |||||||

| LEAN SIX SIGM framework and how dose it work | Meanings of Six Sigma | ||||||

| Data driven decision making | |||||||

| The Problem Solving Strategy Y = f(x) | |||||||

| Understanding How DMAIC and DMADV frame work | |||||||

| Documenting STAKEHOLDER REQUIREMENTS | SIPOC - Identifying stakeholders and customers | ||||||

| Determining critical requirements | |||||||

| Identifying performance metrics | |||||||

| QFD - Quality Function Deployment | |||||||

| Voice of the Customer, Business and Employee | |||||||

| DEFINE PHASE tools | Project selection, Project prioritization, KANO Model, Juran's customer needs | ||||||

| Preparing project charter | |||||||

| Initiating teams, Stages of team evolution | |||||||

| Mapping As - is process flow | |||||||

| Understanding Critical to Quality (CTQ) and VOC to CTQ drill down | |||||||

| Cost of Poor Quality (COPQ) and its types | |||||||

| MEASURE PHASE tools | Understanding of Data , Types of Data , Dimensions of Data | ||||||

| Population Data (VS) Sample data , Sampling Techniques | |||||||

| Sample Size calculation, Confidence level and confidence interval | |||||||

| Data collection template and techniques | |||||||

| Measurement system analysis - Calibration, Gauge R&R, KAPPA analysis | |||||||

| Central Limit Theorem | |||||||

| Stability and Distribution types | |||||||

| Descriptive statistics (Measure of central tendency & Measure of variation) | |||||||

| Base Line sigma calculation (DPU, DPMO, Cp,Cpk) | |||||||

| ANALYZE PHASE tools | 7 QC Tools (Histogram, Cause-and-Effect Diagrams / Fishbone Diagram, Pareto charts, Control Charts, Scatter diagrams, Process Mapping, Check Sheet) | ||||||

| 5 Why Analysis , Control impact matrix, Tree Diagram, Affinity clustering | |||||||

| Data visualization - Box Plot, Multi Vari charts Trends and comparison charts | |||||||

| Hypothesis testing - Parametric test (Continuous Data , Discrete Data) Alpha & Beta errors | |||||||

| LEAN METHODOLOGY | Fundamentals of lean , 5 principles of lean | ||||||

| Value add (VS) non value add and 8 Types of deadly waste | |||||||

| Value stream mapping - Lead Time, Processing Time, Cycle Time, Turnaround Time, First Pass yield, Rolled Throughput Yield, Process Cycle Efficiency | |||||||

| Heijunka - Leveling, Sequencing, Stability, TAKT time | |||||||

| Jidoka, Poke Yoke, Autonomation, Built-in Quality, Stopping at Abnormalities | |||||||

| Visual Management, 5 S implementation | |||||||

| JIT (Just in time), Critical level of replenishment , Supermarket or consumption based replenishment, Kanban | |||||||

| Build a Culture of Kaizens | |||||||

| Visual Workplace | |||||||

| LEAN action workouts , LEAN war rooms | |||||||

| Kaizen, LEAN action work out (AWO) | |||||||

| IMPROVE PHASE tools | Solution design matrix, Brain storming | ||||||

| Failure Mode effect analysis | |||||||

| Regression techniques - Simple linear regression , Multiple regression | |||||||

| Design of experiments (DOE), Taguchi robustness concepts | |||||||

| Basics of solution generation through "Design Thinking Concepts" | |||||||

| "Six Thinking Hats" - Dr. Edward de Bono | |||||||

| CONTROL PHASE tools | Statistical process control | ||||||

| Control plan for sustaining benefits | |||||||

| Introduction to Control Charts and Types of Control Charts | |||||||

| Digital transformation champion | Understanding the fundamentals of Digital transformation | ||||||

| Digital readiness index | |||||||

| Industry 4.0 and digital solution implementation in shop floor | |||||||

| Industrial Internet of things (IiOT) | |||||||

| Robotics Process Automation (RPA) deployment in enterprises services | |||||||

| Design Thinking Champion | Demystifying Design Thinking | ||||||

| Design Thinking approach | |||||||

| Design Thinking tool kit | |||||||

| Applications of Design thinking and success stories | |||||||

| PROJECT DOCUMENTATION and Sustenance | CBA - Cost benefit analysis | ||||||

| Project documentation as per DMAIC frame work | |||||||

| Horizontal deployment of lessons learned | |||||||

| Inculcating LEAN SIX SIGMA DNA in all layers of organization | |||||||

Six Sigma opens up plenty of career opportunities. The potential for job growth will increase along with the overall pay. Those trained in this course can easily expect openings exclusively offered to them. Those trained in this methodology have lucrative ideas and are respected and sought after in their field. Six Sigma Black Belt training can help in several ways and is widely applicable in every domain and process. Individuals looking to excel can easily tap into these training courses and get on the fast track to a successful career.

- Defect Reduction: Lowers scrap and rework rates.

- Cycle-Time Compression: Speeds up production lines for higher throughput.

- Waste Elimination: Identifies non–value-add steps (overproduction, waiting, excess motion).

- Cost Savings: Improves yield, driving down per-unit costs.

2. Healthcare Sector

- Patient Safety & Quality: Reduces medical errors and adverse events.

- Process Standardization: Streamlines patient flow, from admission to discharge.

- Resource Optimization: Cuts down on overtime, bed-turnaround time, and inventory waste.

- Staff Engagement: Empowers clinicians with data-driven problem solving.

3. IT & Software Industry

- Defect Prevention: Lowers bug rates and post-release incidents.

- Agile Integration: Enhances sprint planning with DMAIC-style retrospectives.

- Lead-Time Reduction: Speeds up development and deployment cycles (CI/CD).

- Customer Experience: Improves uptime, performance, and support processes.

4. Banking & Financial Services

- Error-Free Transactions: Minimizes exceptions in loan processing, payments, and reconciliations.

- Regulatory Compliance: Strengthens controls to meet audit and KYC requirements.

- Process Throughput: Accelerates account opening, claims processing, and card issuance.

- Risk Management: Applies statistical tools to detect and prevent fraud.

- On-Time Delivery: Tightens lead times and improves order-fulfillment accuracy.

- Inventory Optimization: Balances stock levels to reduce holding costs.

- Network Efficiency: Streamlines routing, warehousing, and cross-docking.

- Supplier Performance: Implements scorecards and continuous-improvement programs.

- Checkout Speed: Cuts queue times and cart-abandonment rates.

- Demand Forecasting: Applies data analysis to optimize promotions and stock.

- Returns Management: Reduces returns rate through quality checks and packaging improvements.

- Customer Satisfaction: Improves NPS by eliminating pain points in the shopping journey.

7. Telecom Industry

- Network Reliability: Pinpoints causes of outages and reduces mean time to repair.

- Process Automation: Streamlines service-provisioning and billing workflows.

- Customer Care: Cuts call-center handle times and escalations.

- Capacity Planning: Uses statistical models to forecast bandwidth needs.

8. Construction & Engineering

- Project Timeliness: Identifies critical-path delays and bottlenecks.

- Cost Control: Tracks variance and implements corrective actions before overruns.

- Safety Improvements: Applies root-cause analysis to incident prevention.

- Quality Assurance: Standardizes inspections and reduces rework.

9. Power and Energy

- Improved Equipment Reliability

- Operational Efficiency

- Reduced Transmission & Distribution Losses

- Enhanced Safety & Compliance

- Improved Project Delivery

- Energy Efficiency & Cost Savings

- Enhanced Customer Service

- Sustainability & Green Goals

10. Automobile Industry

- Improved Product Quality: Minimizes defects and rework in manufacturing through statistical process control (SPC).

- Ensures compliance with global quality standards (IATF 16949, ISO 9001, etc.).

- Helps achieve zero-defect manufacturing goals.

- Reduced Production Costs : Eliminates waste (Muda) such as overproduction, excess inventory, and downtime. Optimizes resource utilization (materials, manpower, and machines). Lowers cost-per-unit without compromising on quality.

- Faster Time-to-Market: Speeds up new product development by applying Design for Six Sigma (DFSS) and value stream mapping. Streamlines approvals, testing, and validation cycles. Enhances responsiveness to market changes.

- Efficient Supply Chain Management: Improves supplier quality and delivery performance through Six Sigma metrics. Reduces lead times, stockouts, and excess inventory. Supports Just-in-Time (JIT) and Lean inventory practices.

- Enhanced Customer Satisfaction: Reduces warranty claims, breakdowns, and service issues. Delivers consistent product quality, reliability, and performance. Boosts brand loyalty and positive customer feedback.

- Improved Safety & Compliance: Applies FMEA and Root Cause Analysis to reduce product safety risks and ensure regulatory compliance (e.g., safety ratings, emissions). Enhances process safety on the shop floor.

- Standardized & Scalable Processes: Ensures consistency across global manufacturing plants. Supports scaling of best practices across divisions and suppliers.

- Data-Driven Decision Making: Encourages use of Six Sigma tools (Pareto, regression, control charts, DOE) to make informed process improvements. Improves predictive maintenance, quality tracking, and production planning.

Lean Six Sigma Certified Salary – What You Can Expect

Lean Six Sigma certifications significantly boost earning potential, especially at the Green Belt and Black Belt levels. Salaries vary by role, industry, and location, but here’s a general overview based on global and India-specific trends:

Global Average Salaries (USD)

- Lean Six Sigma Green Belt $75,000 – $95,000

- Lean Six Sigma Black Belt $95,000 – $120,000+

- Lean Six Sigma Master Black Belt $120,000 – $150,000+

India Average Salaries (INR)

- Lean Six Sigma Green Belt ?8 LPA – ?13 LPA

- Lean Six Sigma Black Belt ?15 LPA – ?22 LPA+

- Lean Six Sigma Master Black Belt ?26 LPA – ?40 LPA+

Salary Depends On:

- Industry (higher in consulting, manufacturing, IT, healthcare, and BFSI)

- Experience and previous project success

- Geography (metro cities typically offer higher compensation)

- Role/Function (Operations, Quality, Process Excellence, etc.)

Bonus Advantage

- Many professionals also earn performance bonuses for successful Lean Six Sigma project outcomes, sometimes as high as 10–25% of their base salary.

The Combo, Lean Six Sigma Green Belt, and the Black belt are best suited for the one who wishes to learn and understand the lean six sigma application from basic to advance level.

The combo takes you from the very basic six sigma curriculum to advance Black Belt Six Sigma DFSS topics with live project implementation and end-to-end Minitab Pro data simulations.

There are no eligibility criteria or educational/professional background requirements for this combo.

A tentative list of professionals who most often go for this combo is listed below. This list is just an idea of professionals seeking Lean Six Sigma Combo.

- Senior Management

- Financial/Business Analyst/Quality Analyst/ Quality Assurance

- Commodity Manager, Logistics, Supply Chain Professional

- Project Manager, Delivery Manager, Project Owner, Lead

- Quality Manager, Plant Head, Factory Head/Supervisor

- Production Manager/ Engineer/ Executive

- Six Sigma Consultant

- Business Development Manager

- Manufacturing Process Engineer

- Continuous Improvement Director

- Business Managers or Consultants

- Project Manager/Program Manager

- Management students

- Team leaders

- Software Professionals

- If a company intends to implement Six Sigma, then the management of the company needs to be Certified

- Quality Assurance Engineers

- Software Quality Assurance team members

- Director or VP of Operations, & Business Excellence

- CEO, CFO, CTO

On successful completion of the combo course and course requisites, the candidate will receive Internationally Recognized and World’s Highest Accredited Certified Lean Six Sigma Green Belt Certification & Certified Lean Six Sigma Black Belt Certification.

The certification is accredited by CSSC, American Board USA & UKAC United Kingdom. The certification acknowledges the Course outline and curriculum of The American Society for Quality.

The Certification follows best practices as defined by ISO/IEC 17024.

This course offers the Six Sigma Certification Validation Tool for Employers

Your Six Sigma Certification Validation Tool can be used by employers, clients, and other stakeholders to validate the authenticity of the Six Sigma Certifications you have received. Using the program code located on your certified CLSSGB & CLSSBB certification, one can see all your training and certification details online.

.jpg)

.webp)